In this guide I will show you how to give your old wood floor a new and fresh Nordic look. The floor in this guide is from my own apartment where a doll gray carpet has covered it for many years. After I took over this apartment this old floor was high on my to-do list to get fixed.

In the following I will describe how I sanded and later lye and oil treated my floor. There are of cause several different ways and techniques to make a floor like mine. You should therefore always follow the instruction from your local paint shop where you also can buy all the stuff you need for this project. Especially, in the lye and oiling process is important to follow the instructions provided on the labels as this may be different from brand to brand.

Renovating My Floor

Instead of rolling out a new carpet, I removed the old one and the original wooden floor was revealed underneath. Because the floor had been protected by the carpet for many years it was in quite good shape.

It was an easy decision for me to keep the beautiful floor and give it a new and fresh look with some white colored lye and oil. This kind of treatment is very popular in Denmark and the other Nordic countries in general. Almost all newly built houses have some kind of white oil colored floors. I think it is because it gives a nice and light feeling in the room. I know that it is popular with heavy carpets in many countries - in the Nordic design you would never uses full floor carpets.

Treatment with Oil and Wood Lye

Even though the floor was in good shape, I decided to have the floor sanded to make it stand out as completely new as possible. A newly sanded floor is beautiful to look at but it is completely open to all dirt and other stuff. Therefore, it is important that the floor is sealed with a good oil. The oil will act as a kind of coating of the wood preventing the it from getting dirty when using the floor. However, before the oil is painted on the floor it is also a good idea to treat the floor with a wood lye. The lye is easy to apply and it will sucked into the wood preventing it from being discolored over time mainly due to the UV light coming from the sun.

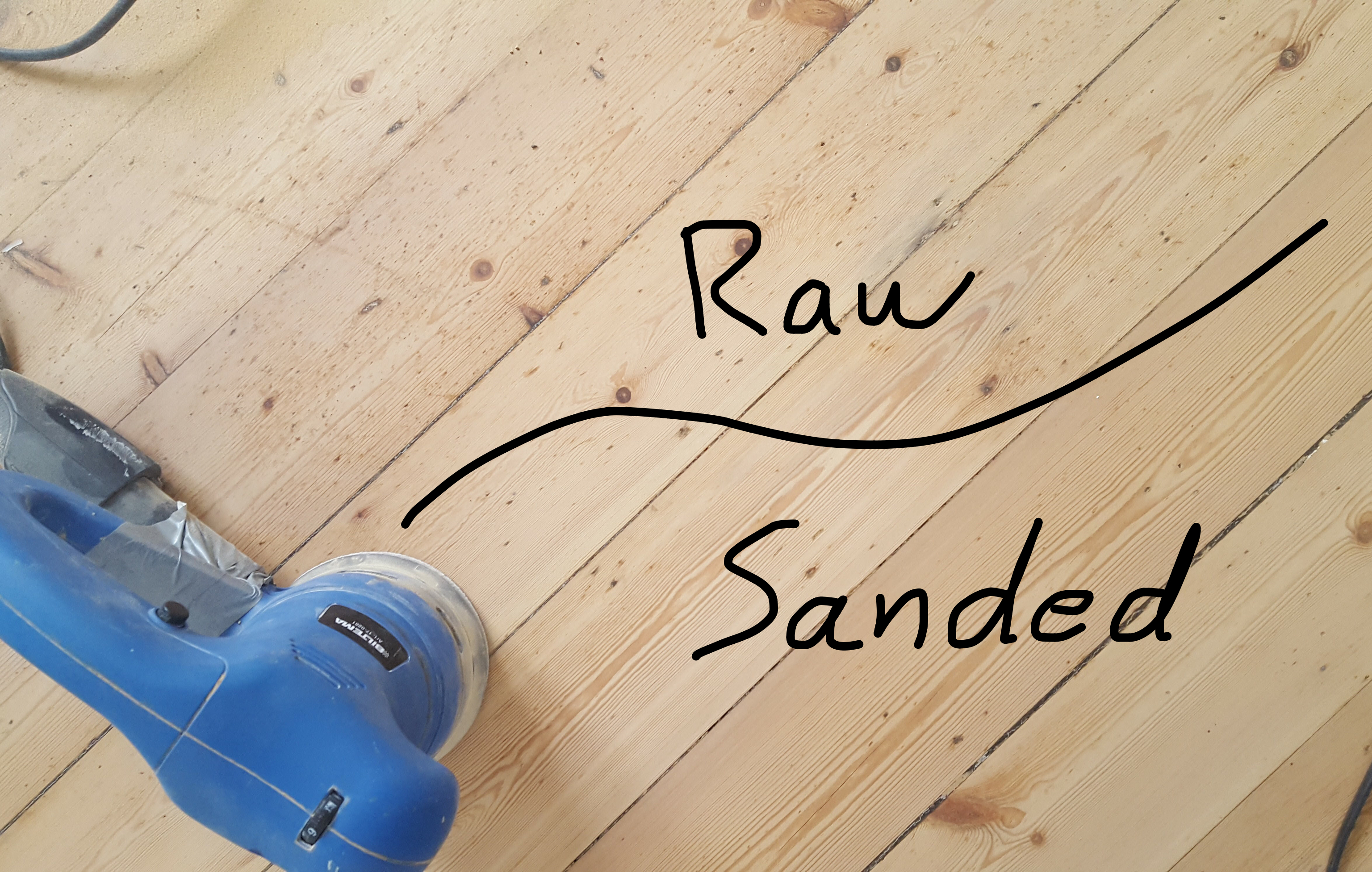

Step 1: Sanding of the Floor

Depending on the size of your floor I would recommend you to rent a professionel wood sanding machine. It is normally not that expensive and it will do a good job. Remember to ask for instructions and some good tips from the rental company. In Denmark you can rent these machines from local hardware stores - I would believe it is possible that you can do the same at your local hardware store. Depending on how you floor is previous treated your might need special sand paper. Again, the rental place can help you there.

My floor is not that big and because it has been protected by a carpet I was able to sand the entire floor using my small orbital sander. It differently took a bit longer compared to a large and professional machine. However, then I saved the money on the rental of a professional machine and the time to and from the hardware store.

When sanding the floor always try to move the orbital sander along the wood grains. Then you will avoid making noticeable grinding marks.

Step 2: Treating with Wood Lye

Wood lye is mainly used for priming newly sanded or unfinished wood. The main reason for treating your floor with wood lye is to prevent/reduce the natural yellowing process of your floor. It will also give the wood a lighther/whither color if you decide to use the colored lye like I did. Wood lye is only a pertreamtment and cannot stand-alone. You would always have to continue treating your floor with wood soap or oil. I decided to treat my floor with oil, which I will describe in the following steps.

1: After the sanding of the floor; apply an even layer of wood lye all over the floor. Then leave it for about 20 minutes, so that it have had the time to be sucked into the wood. During this time, it is important that the floor has a fully covered layer of lye all the time. If you see dry spots apply some more lye in this area.

2: After 20 minutes I used some old clothes or cloths to polish the rest of the lye into the floor. I know that some types of lye should be left on without the polishing step. I personally prefer this step where the lye is polished to make sure that you do not get any spots where the lye did not dry evenly. This can otherwise result in noticeable spots in the final result.

This might sound like it is difficult to do - however, just remember two things; no dry spots and always an even layer.

3: When done, let the floor dry for about 8 hours and then use a piece of sandpaper grain size 120 to lightly sand the floor. When applying wood lye to a freshly sanded floor some of the wood fiber will rise a little bit. That is why it is a good idea to lightly sand it again.

4: Vacuum before continue with the next step.

Step 3: Treating with Wood Oil

After the floor has been sanded and treated with wood lye, then it is time to seal of the wood with some good floor oil. This is an important step because this will keep the floor nice for many years.

Always follow the instructions on the bottle of the oil. However, below I will list the instructions how I applied the oil with a good result.

1: Apply the oil to the floor using a wide brush. It is a good idea to spend some money on a quality brush otherwise you risk that the hairs will come off and get stock in the wet oil. Like the wood lye, it is important that the floor has an even layer of oil for about 10-15 minutes. If you see some dry spots apply some more oil in that area. If you have a larger floor I will recommend you to work on smaller areas of the floor and then complete the entire floor in several steps. Just remember always to work wet-in-wet. If you let parts of the area dry and then continues with the oiling at a later point - then you might be able to see this intersection in the finished floor.

2: After the area/spot of the floor has been covered in oil for about 15 minutes, use a scraper to scrape any exceeding oil to the next part of the floor. Then use a polishing machine or some old clothes to polish the oiled part. Continue until you are done with the entire floor. Make sure to do the entire floor in one work session. If you let parts of oil cure then you can risk of getting an uneven color.

3: When the entire floor is oiled and polished, it is time to let the oil cure. The type of oil I used took 8 hours before I could gently walk on it. The total curing time was 7 days. It is very important to remember that using some types of wood oil can cause the used polishing cloths to self-ignite - always add a lot of water to the cloths after you are done with them.

Questions or comments

I will be happy if you would leave a comment in the comments section below. You are also very welcome to ask questions. I will try to answer the best I can.

karen w

Hi there! We also ripped up a carpet, but to find some plywood boards along with a mostly good wood floor. The plywood only makes up a small fraction of the room, and is where they extended the house out at one time. Anyway, I saw a light/white wood floor on another blog, and I thought that refinishing the floor with a "white wash" might make the transition from good to ply wood less obvious.

I followed some instructions that talked about using white wood oil - which I found (WOCA) - and after sanding, I've applied the wood oil on the plywood (far end of the room) and about one third of the good boards.

Problem = the wood isn't really white at all. It looks nice, but doesn't have that whitish look. Now I've read that perhaps I should've used the white wood oil "color" (which I didn't know there was) or have used the lye - as you did.

What do you recommend from here? I do want it to be lighter, however I have a new bottle of wood oil (not the color kind, but white) coming in a few days since I didn't have enough. I could return it, but wondering if I should try the white oil color (or whatever it is) even though I've already put oil on some of the floor. Not sure if you know about this...but thought I'd try you. As I understand it it'd be too late to use the lye, right?

Well, any ideas/suggestions would be appreciated. I don't want to be sorry I didn't do it right the first time.

thanks - karen

Kim Nielsen

Hi Karen. I think that I understand your issue. The problem is that 'white' wood oil typically don't contain that much color. The white color you see on a typical Nordic floor comes from the white lye. The lye is what gives the white look. I'll not recommend applying lye on a floor which has been treated with oil already. The oil seals off the floor so the lye will not be able to go into the wood. What I suggest is that you could sand the floor to get rid of all the oil and then start over with lye. However, I guess you would need some semi-professionel equipment to sand of the oiled floor away. I hope this could help you a little. Regards Kim

Lynne Marie

Hello!

Thank you so much for this very helpful article.

We are in the process of sanding our floors and want them to look exactly like yours when we are done so maybe you can tell me some more details if you have a moment.

We have some questions:

Which products specifically did you use as a wood lye and for wood oil. (we are in Germany and might be able to get the exact ones, so the brand would be also quite helpful)

Also, when you sanded your floors, before you applied the lye, what was the sanding grit progression you used? We are sanding with a 40 grit paper and thinking 80 is next and after that 120. (My husband REALLY wants to just jump straight to the 120, but I am not so certain)

Also, how are your oiled floors holding up? Your article is over a year old, maybe you have an update or even some pictures? We are trying to be realistic about how much care these floors are going to need, so any words of wisdom would be so amazing!

Cheers!

Lynne Marie

Kim Nielsen

Hi Lynne. I sanded the floor using only two different types of grit papers. I started with the 40 or 80 I can't remember exactly and then I finished with the 120. You can get a perfect fine result with only two grinding steps. Regarding the brand of oil and lye - We have two very good products/brands here in Denmark called Faxe and Trip Trap Woodcare both a really great (In Denmark you can get the Trip Trap Woodcare at Bauhaus). But you can use any type of lye and oil products which are designed for floors. My floor is still great after three years of use. It's a good idea to spend some extra effort when polishing the lye and oil into the floor. If you do a good job at these steps, then you get a good result. Try to really massage the oil into the wood. Also, when buying the products you should also get a care product which is used to wash/treat the floor regularly (I only wash the floor 4-5 times a year).

Elena

Hello Kim,

Question - we have sandpapered the whole floor with 120 grit and thinking of applying lye and afterwards finish it with soap (Danish style). Do we need to sandpaper the floor at 150 grit or higher before applying the finishing soap or will 120 be enough?

Thank you!

Kim Nielsen

Hello Elena

If you are happy with the result after sanding with 120 grit then I would not go with the 150 grit. I would say that 120 grit would be good enough. Soap style is a good solution just remember that it takes several years of washing the floor each month before the floor is saturated with the soap. But when the floor is fully saturated with soap I believe that you get a "stronger" floor compared with lye and oil. I hope this answers your question. Regards Kim (NordicFoodLiving.com)

Rhonda Marie Jean

Hi Kim.

I'm looking to install white oak or ash wood for the whitest non yellowing flooring.

Since I have a 100 lbs white akita, is it better to lye the wood then top with a few coatings of Bona traffic HD seal as opposed to oil? I'm wanting the "whit" nordic matte look. Any suggestions are greatly appreciated.